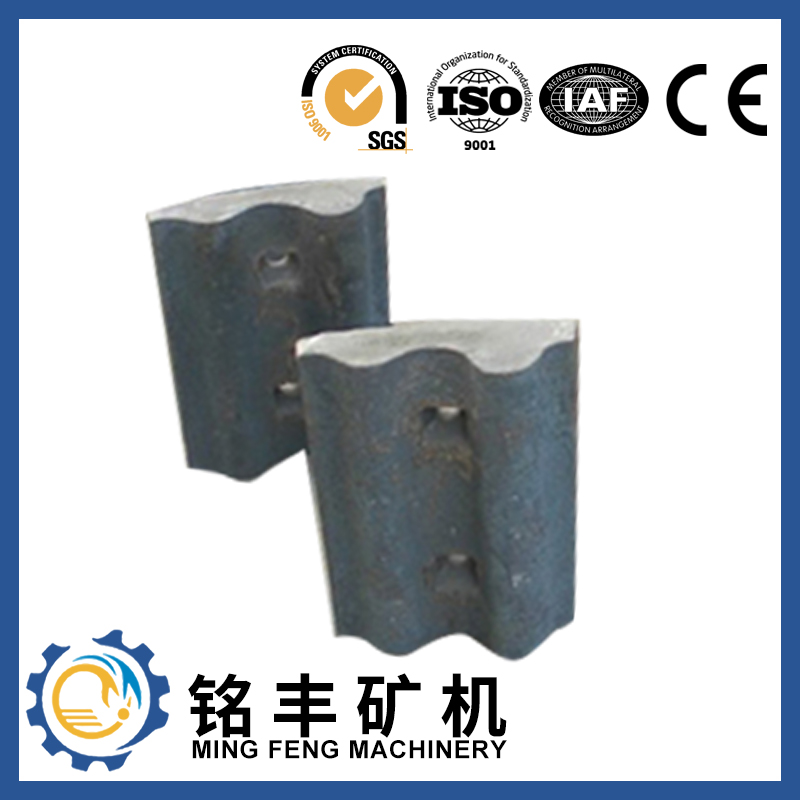

Awet mining ball mill liner

Ringkesan:

| Jinis | Crusher liner board, lining plate | ||

| asale | Cina | Kode HS | 84749000 |

| kahanan | Anyar | Penggilingan bijih | Kuarsa, bijih emas, klinker semen, lsp. |

| Jinis Mesin | Ball Mill Liner | Sertifikasi | ISO 9001:2008 |

| Bahan Utama | Mn13Cr2 , Mn18Cr2, Mn22Cr2, Cr22, Cr26 | ||

| Jinis Pangolahan | Casting | Perawatan lumahing | Polishing / Semprotan Paint |

| Inspeksi Casting | Instrumen Spektrum Langsung-maca, Analisis Metalografi, Inspeksi Ultrasonik, Inspeksi Partikel Magnetik, Inspeksi Sifat Mekanik | ||

| Paket Angkutan | Dikempalken ing Pallet / Case | Njamin | Padha karo Original |

| Kualitas | Tingkat Dhuwur | Pengalaman | Luwih saka 30 Taun |

Bahan sing ditrapake:

Kerikil kali, granit, basalt, bijih besi, watu gamping, kuarsa, diabase, bijih besi, bijih emas, bijih tembaga, dll.

Kondisi kerja:

halaman pasir-kerikil, pertambangan tambang, pertambangan batu bara, stasiun pencampuran beton, mortar kering, desulfurisasi pembangkit listrik, pasir kuarsa, dll.

| Komposisi Kimia Bahan Casting Manganess Dhuwur | |||||||

| Kode Elem. | C | Mn | Si | Cr | Mo | P | S |

| ZGMn13-1 | 1.0-1.45 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-2 | 0.90-1.35 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-3 | 0.9-1.35 | 11.0-14.0 | 0.30-0.8 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-4 | 0.9-1.30 | 11.0-14.0 | 0.30-0.8 | 1.50-2.0 | - | ≤0.09 | ≤0.04 |

| ZGMn13-5 | 0.75-1.30 | 11.0-14.0 | 0.30-1.0 | - | 0.90-1.2 | ≤0.09 | ≤0.04 |

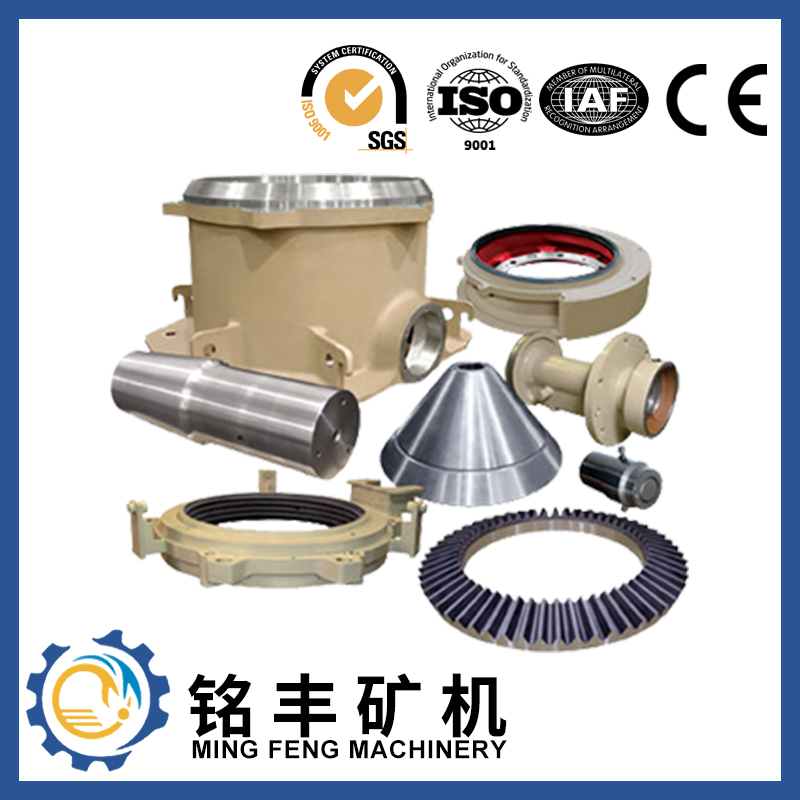

Bagian Crusher:

Kita duwe suku cadang crusher pengganti mesin presisi kalebu kepala, mangkuk, poros utama, liner soket, soket, bushing eksentrik, bushing kepala, gear, countershaft, bushing countershaft, omah countershaft, liner kursi mainframe lan liya-liyane, kita bisa ndhukung kabeh mesin sampeyan. suku cadang mekanik.

Apa milih kita?

1.30 taun pengalaman manufaktur, 6 taun pengalaman perdagangan manca

2. Kontrol kualitas sing ketat, laboratorium dhewe

3. ISO9001:2008, BIRO VERITAS

PRODUK HOT-SALE

Quality First, Safety Dijamin