Bar jotosan impact kanggo Np2023 umum

Ringkesan:

| Jinis | Bar mangkok | ||

| asale | Cina | Kode HS | 84749000 |

| kahanan | Anyar | Industri sing ditrapake | Energi & Pertambangan |

| Jinis Mesin | Impact Crusher | Sertifikasi | ISO 9001:2008 |

| Kekerasan | HRC58 - HRC63 | Kapabilitas Produksi | Luwih saka 10000 ton / taun |

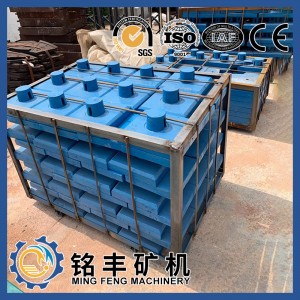

| Jinis Pangolahan | Casting | Perawatan lumahing | Polishing / Semprotan Paint |

| Tes Produksi | Tes kekerasan, uji metalografi, analisis spektral, sifat mekanik lan perawatan panas. | ||

| Paket Angkutan | Dikempalken ing Pallet / Case | Njamin | Padha karo Original |

| Kualitas | Tingkat Dhuwur | Pengalaman | Luwih saka 30 Taun |

| Komposisi Kimia Bahan Casting Manganess Dhuwur | |||||||

| Kode Elem. | C | Mn | Si | Cr | Mo | P | S |

| ZGMn13-1 | 1.0-1.45 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-2 | 0.90-1.35 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-3 | 0.9-1.35 | 11.0-14.0 | 0.30-0.8 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-4 | 0.9-1.30 | 11.0-14.0 | 0.30-0.8 | 1.50-2.0 | - | ≤0.09 | ≤0.04 |

| ZGMn13-5 | 0.75-1.30 | 11.0-14.0 | 0.30-1.0 | - | 0.90-1.2 | ≤0.09 | ≤0.04 |

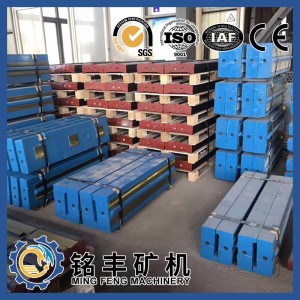

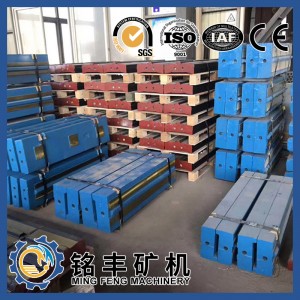

Bagian nyandhang kanggo impact crusher utamané kalebu: jotosan bar, impact plate, sisih piring etc.

Gunakake: Quarry, Mining, Agregat Semen, Daur Ulang, Shredding, Demolition Fields.lsp.

Proses produksi:

1. Pola Inspeksi

2. Molding

3. Nyiram

4. Perawatan panas

5. Raw Casting pengawasan

6. Inspeksi Maching

7. Non-destruktif Testing

8. Pemriksaan Akhir

9. Pangiriman

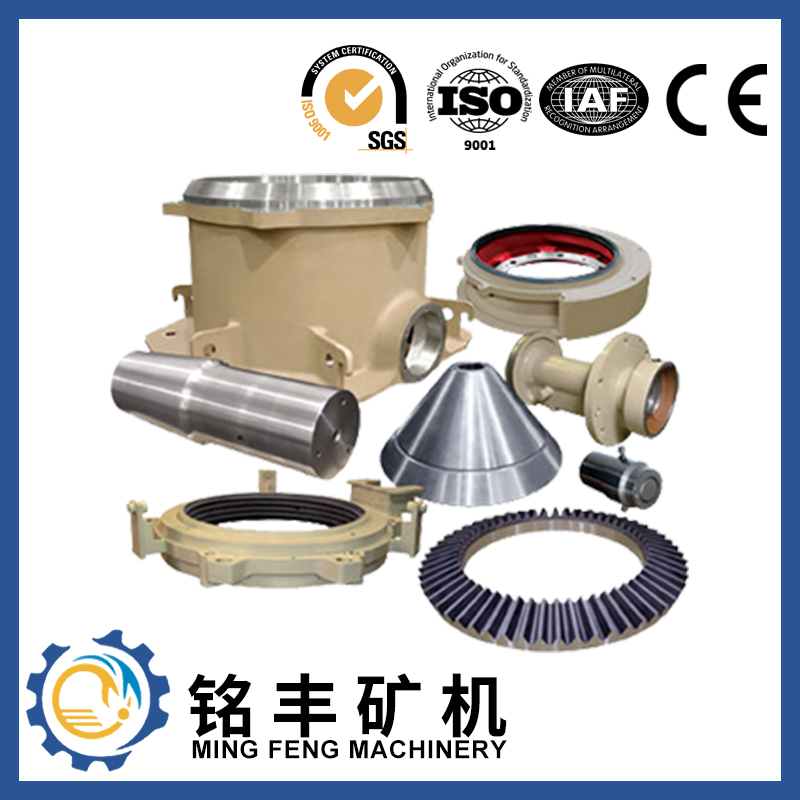

Bagian Crusher:

Kita duwe suku cadang crusher pengganti mesin presisi kalebu kepala, mangkuk, poros utama, liner soket, soket, bushing eksentrik, bushing kepala, gear, countershaft, bushing countershaft, omah countershaft, liner kursi mainframe lan liya-liyane, kita bisa ndhukung kabeh mesin sampeyan. suku cadang mekanik.

Ora duwe model sing sampeyan butuhake?

Ora duwe model sing sampeyan butuhake?

Kita nggarap gambar teknis kanggo produk sing ora standar.Yen pesenan kanggo bagean standar, sampeyan mung kudu menehi nomer bagean supaya kita bisa nemtokake bagean pesenan.

PRODUK HOT-SALE

Quality First, Safety Dijamin