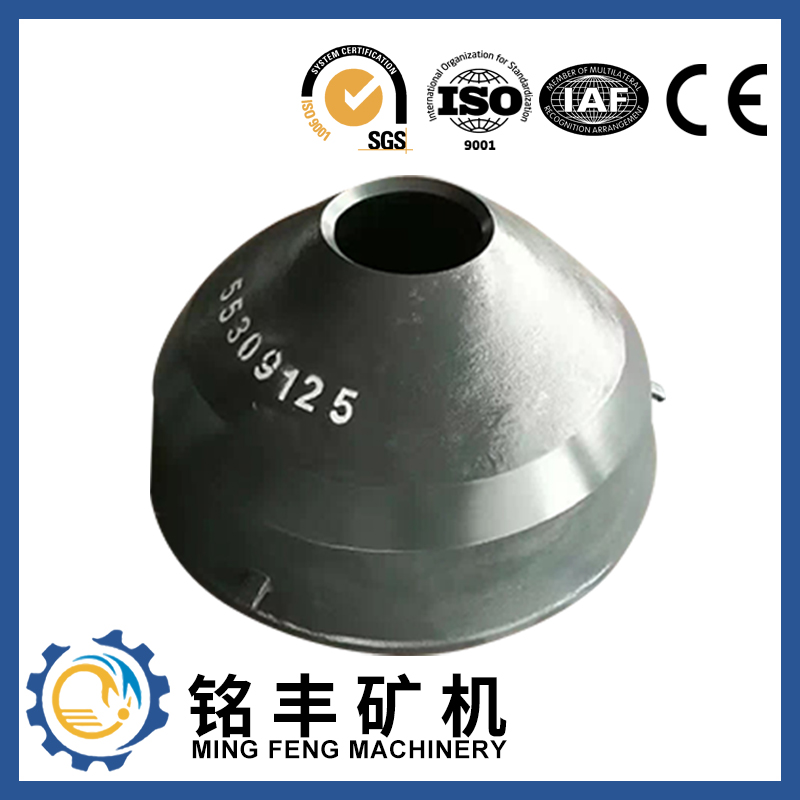

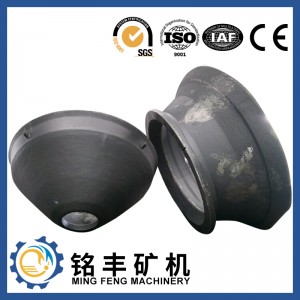

OEM umum HP3 crushing cones-N55309125

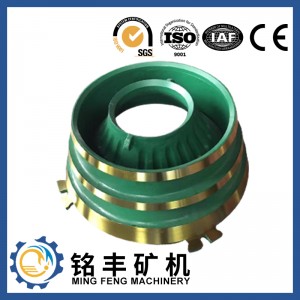

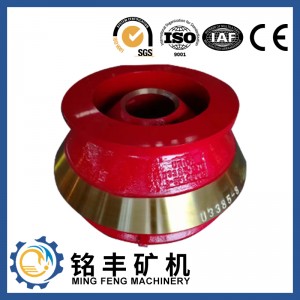

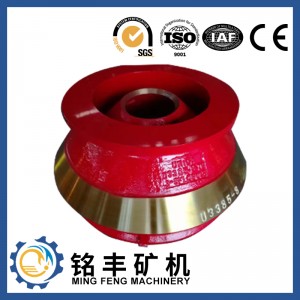

Ming Feng punika Produsèn OEM profesional, kita mrodhuksi manganese nyandhang liners lan aksesoris kanggo paling merek crushing kalebu umum, sandvick, Symons, umum., Telsmith, Terex, Pegson, Lokomo, Kleeman, Hazemag lan liyane.Paling bagean kasedhiya ing 13%, 14%, 18% lan 22% wesi manganese.Nganggo liner kaya mantel, mangkok liner / cekung kanggo cone crusher, pipi piring lan rahang piring kanggo rahang crushers lan jotosan bar kanggo Horizontal Shaft Impactors kasedhiya!

Ringkesan:

| Jinis | Bowl Liner, Concave Ring, Cone Liner, Mantel Liner | ||

| UtamaModel | seri HP | HP3 HP6 HP100 HP200 HP300 HP400 HP500 HP700 HP800 HP4 HP5 | |

| GP seri | G8 G11 G12 G15 GP100S GP200S GP300S GP500S GP7 GP100 GP200 GP300 GP500 GP220 GP330 GP550 | ||

| asale | Cina | Kode HS | 84749000 |

| kahanan | Anyar | Industri sing ditrapake | Energi & Pertambangan |

| Jinis Mesin | Cone Crusher | Sertifikasi | ISO 9001:2008 |

| Kekerasan | HB220~240 | Kapabilitas Produksi | Luwih saka 42000 ton / taun |

| Jinis Pangolahan | Casting | Perawatan lumahing | Polishing / Semprotan Paint |

| Inspeksi Casting | Instrumen Spektrum Langsung-maca, Analisis Metalografi, Inspeksi Ultrasonik, Inspeksi Partikel Magnetik, Inspeksi Sifat Mekanik | ||

| Paket Angkutan | Dikempalken ing Pallet / Case | Njamin | Padha karo Original |

| Kualitas | Tingkat Dhuwur | Pengalaman | Luwih saka 30 Taun |

Seri Mangan dhuwur

Nganggo Parts kanggo peralatan Mining

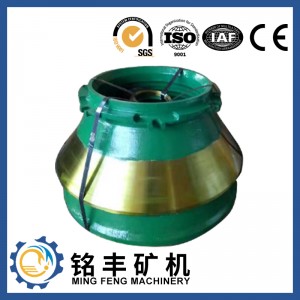

Aplikasi utama kanggo panggunaan resistensi nyandhang dhuwur kayata piring Jaw crusher, Cone crusher bowl liner, Impact crusher lining board, Ball mill liner lan link chain kanggo Dredge ect.

Advatages kita

1.teknologi KALUBÈRAN, produksi majeng, peralatan Processing canggih lan fasilitas pengawasan rampung

2. Saben proses dikontrol lan saben mesin lan spare parts dipriksa.

3. Kita bakal nyedhiyani layanan siji-mandeg, nelusuri wektu nyata lan kerjasama sampeyan.

4. Sah dening sistem kualitas ISO9001 Nasional.

Bahan

1). High Manganese Casting:

Mn13, Mn18, Mn22, Mn13Cr2, Mn18Cr2, Mn22Cr2, Mn13CrMo, Mn13CrMoNi…

2). Baja Krom Tinggi:

Cr13, Cr15, Cr18, Cr20, Cr25, Cr27, Cr15Mo1, Cr18Mo1,

Cr25Mo0.5Ni0.5…

3) Sembarang materi liyane minangka requirement customer kang.

Komposisi Kimia Bahan Casting Manganess Tinggi(%)

| Kode Material | C | Mn | Si | Cr | P | S |

| ZGMn13Cr2 | C:0.9-1.3 | Mn: 11.0-14.0 | Si: 0.3-1.0 | Kr: 1.5-2.5 | P: ≤0.06 | S: ≤0.04 |

| ZGMn18Cr2 | C:1.1-1.5 | Mn: 16.5-19.0 | Si: ≤0.8 | Kr: 1.5-2.5 | P: ≤0.07 | S: ≤0.04 |

| ZGMn22Cr2 | C:1.1-1.4 | Mn: 20-24 | Si: ≤0.8 | Kr: 1.5-2.5 | P: ≤0.07 | S: ≤0.04 |

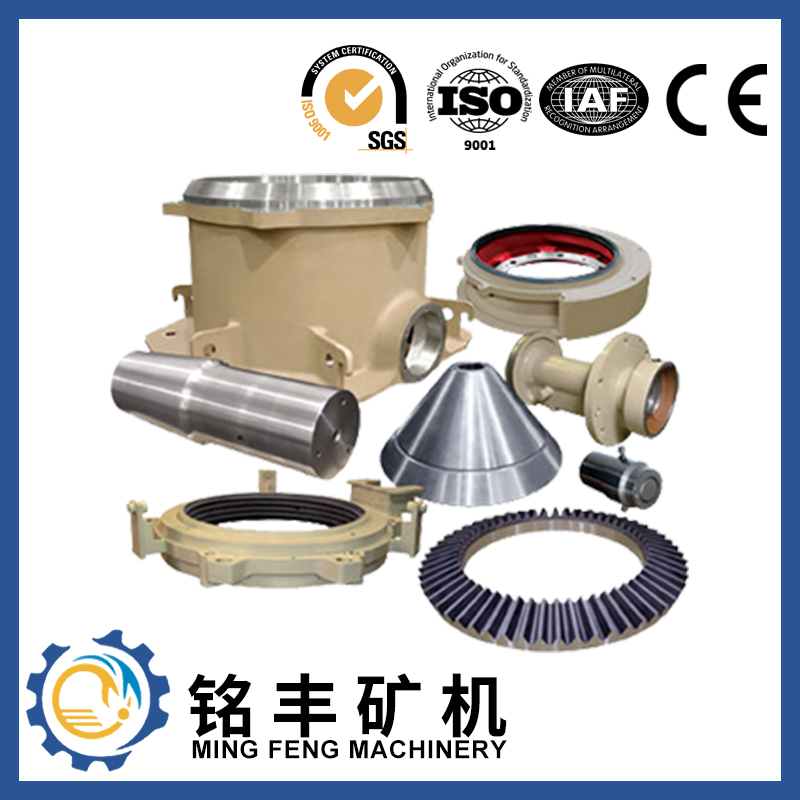

Bagian Cone Crusher:

Kita duwe suku cadang crusher pengganti mesin presisi kalebu kepala, mangkuk, poros utama, liner soket, soket, bushing eksentrik, bushing kepala, gear, countershaft, bushing countershaft, omah countershaft, liner kursi mainframe lan liya-liyane, kita bisa ndhukung kabeh mesin sampeyan. suku cadang mekanik.

Apa milih kita?

1.30 taun pengalaman manufaktur, 6 taun pengalaman perdagangan manca

2. Kontrol kualitas sing ketat, laboratorium dhewe

3. ISO9001:2008, BIRO VERITAS

PRODUK HOT-SALE

Quality First, Safety Dijamin